Prestations de service sur mesure et expertise R&D en soudage et brasage

Selectarc ne se contente pas d’être l’unique fabricant français de métaux d’apport pour le soudage et le brasage. Notre équipe R&D hautement qualifiée propose également plusieurs prestations de services, telles que les analyses chimiques et mécaniques, le travail à façon et le développement de produits spécifiques selon votre cahier des charges. Contactez-nous pour bénéficier de notre support technique.

Tests et analyses chimiques et mécaniques des produits de soudage

Notre laboratoire est équipé pour réaliser des analyses chimiques et mécaniques :

- Certificats CCPU 3.1 chimie et mécanique / CCPU 3.2 chimie et mécanique (selon EN 10204)

- Produits recettés RCC-M

- Analyses chimiques sur fils

- Tests de dureté : Brinell, Vickers et Rockwell

- Tests de traction à chaud et à froid sur fils

- Tests de pliage

- Essais de flexion par choc (test de résilience)

- Macrographies et micrographies

- Essais sur mesure selon votre cahier des charges

Travail à façon en soudage et brasage : l’expertise qui fait la différence

Selectarc met tout son savoir-faire à votre disposition pour répondre à vos exigences les plus pointues. Nous comprenons que certains projets nécessitent une attention particulière et des compétences spécifiques. C’est pourquoi nous offrons un éventail de services de travail à façon sur mesure sous contrôle qualité, conçus pour répondre aux exigences les plus pointues de nos clients :

- Tréfilage : De diamètres variés pour l’aluminium, les aciers inoxydables, le nickel, le cuivre, et les cobalt alliages

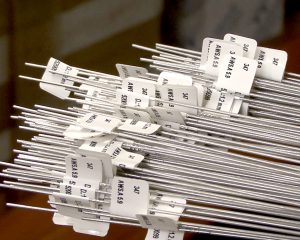

- Dressage et coupe : Précision dans toutes nuances pour des diamètres de 6 à 0,2mm

- Bobinage : Capacité à bobiner divers alliages dans une multitude de diamètres, répondant aux besoins spécifiques grâce à une vaste gamme de bobines

- Traitement, nettoyage, décapage chimique et mécanique : Méthodes garantissant une pureté optimale des alliages, critère indispensable notamment pour les secteurs du nucléaire et de l’aérospatiale

- Mise en forme, marquage, conditionnement, traitement thermique : Services complémentaires offrant une personnalisation et un ajustement aux spécifications particulières

Fabrication sur mesure en soudage et brasage

Notre savoir-faire et notre expertise nous permettent d’élaborer des formulations de produits d’apport sur mesure pour des applications spécifiques en offrant les performances opératoires et mécaniques requises. Ces développements contribuent ainsi à faire progresser l’état de l’art du secteur.

Notre engagement est de fournir des solutions sur mesure, adaptées à chaque demande particulière, chaque application spécifique avec toujours le plus haut niveau d’exigence qualité.

Nous offrons une vaste gamme de possibilités de personnalisation pour nos métaux d’apport de soudage et de brasage, incluant :

- La formulation des produits pour répondre à des exigences spécifiques grâce à notre laboratoire de R&D

- La personnalisation des dimensions telles que le diamètre, la longueur et la forme des produits

- La personnalisation de la couleur de l’enrobage et de l’alliage

- La possibilité de choisir la quantité, la taille et le type de conditionnement

- L’emballage, avec une attention particulière sur le type, la forme, la couleur, ainsi que des options de conditionnement sous vide ou sous argon

- L’identification unique des produits grâce à des options de marquage, de frappe et de drapeautage, sans oublier l’étiquetage personnalisé

- Et la réalisation d’essais sur-mesure, conformes à votre cahier des charges

Support technique en soudage et brasage

Expertise en Soudage et Brasage

Vous avez besoin de conseils techniques, de préconisations en soudage ou brasage, ou de documentation adaptée ? Notre équipe d’experts est à votre disposition pour vous accompagner et vous fournir des solutions personnalisées, adaptées à vos besoins spécifiques.

Accompagnement Technique & Qualification des Procédés

Nous vous assistons dans :

- Le choix des métaux d’apport pour une performance optimale

- La qualification des modes opératoires de soudage (QMOS) et de brasage (QMOB)

- L’optimisation de vos procédés de soudage et brasage pour une meilleure qualité et durabilité des assemblages.

Expertise Métallurgique & Contrôle Qualité

Grâce à notre laboratoire d’analyses métallurgiques, nous effectuons :

- Analyses chimiques du métal déposé

- Essais mécaniques (traction, résilience, pliage)

- Contrôles macrographiques et micrographiques pour évaluer la qualité des soudures et brasures

Nos solutions sont adaptées aux secteurs les plus exigeants, tels que l’aéronautique et l’aérospatiale, le nucléaire et la chimie et pétrochimie.